Working with a seized bolt lacking a head can be incredibly exasperating and can drain both your time and resources. However, equipping yourself with the right techniques to successfully tackle this situation can prove to be a valuable investment, saving you both time and money.

In this guide, you are going to learn an easy way to free rusted screws, and simple solution to a frustrating problem.

What important considerations should be taken?

1. Safety Comes First

Removing a bolt in this state can pose risks, so prioritize safety. It’s vital to don safety glasses, gloves, and other protective gear. Additionally, ensure the work area is free from any potential hazards.

2. Necessary Equipment

You might require specialized tools like penetrating oil, pliers, a wrench, a drill, a tap and die set, a left-handed drill bit, or even a hacksaw. It’s crucial to gather all the necessary tools before starting.

3. Bolt Size and Position

Factor in the size and location of the bolt, especially if it’s in a hard-to-reach spot. This can impact the methods and tools needed for successful removal.

4. Potential Damage

Consider whether removing the seized bolt could lead to damage of surrounding components or the area it’s part of, as well as if the act of removal itself might cause harm.

5. Time and Effort Investment

Be prepared for the significant effort and time it might take to remove the bolt. Having a backup plan in case your initial approach fails is a prudent move.

6. Replacement Consideration

Evaluate whether the seized bolt plays a critical role in the equipment or structure. Reflect on whether its removal would lead to substantial issues. In some cases, it might be more sensible to replace the entire item rather than struggle with bolt removal.

7. Expert Advice

If you’re new to dealing with seized bolts, seeking guidance from an expert or professional is a smart step. This can help prevent potential damage to both yourself and the surrounding environment.

At last, These considerations will aid you in approaching the task of removing a seized bolt with no head in a thoughtful and cautious manner, minimizing risks and increasing the chances of a successful outcome.

How can you remove rusted bolts effectively by following a patient and strategic approach?

Bolts serve a multitude of purposes across various applications, thereby necessitating their presence in diverse settings. To ensure the longevity of bolts, preventing rust is of paramount importance, as rust can gradually degrade them over time.

When confronted with rusted bolts, adopting a patient and strategic approach significantly enhances the likelihood of successful removal. Here’s a step-by-step guide with added linkers to seamlessly connect each point:

Step 1: Assess the Situation

Begin by carefully and thoroughly examining the steel bolt for any visible signs of rust. If rust is detected, it becomes imperative to verify the torque in order to avert the possibility of the bolt snapping.

In situations where the bolt’s condition appears to be beyond salvage, opting for replacement might be the most prudent choice. However, it’s worth noting that employing locking pliers on the J-nut can frequently salvage screws and bolts.

Step 2: Remove Rust from the Metal Surface

Should the bolt be salvageable, your focus should shift towards efficiently removing rust from the bolt’s threads. Here’s how to proceed:

- Start by utilizing a scrubber once the threaded bolt has been removed.

- Instead of opting for abrasive or solvent-based scrubbers, consider utilizing water to effectively eliminate rust.

- Enhance the process by utilizing a wire brush, which can further amplify the effectiveness of rust removal.

Step 3: Select the Right Tools

The process of selecting suitable tools plays a pivotal role in ensuring the successful removal of the bolt. Several factors, including grip and symmetry, should be taken into consideration:

- For a stronger grip, opt for a wrench featuring an open-ended jaw.

- In cases where the bolt lacks symmetry, a wrench equipped with a six-pointed jaw proves to be a more efficient choice.

- For more in-depth guidance on this matter, you can refer to the resource “How to Choose the Right Impact Wrench: Bolt Like a Pro.”

Step 4: Follow Directions

Precision matters when dealing with bolt removal. To avoid any confusion between left and right directions while turning the bolt, utilize your left hand to turn it clockwise. This approach should take into account your position relative to the bolt.

Step 5: Apply a Liquid Thread Loosener

Explore innovative methods for loosening stubborn rusted bolts. You can consider using a liquid thread loosener, penetrating oil, or even a concoction of acetone and liquid ATF to effectively address this challenge.

Step 6: Soak the Bolts

Enhance the removal process by allowing old, rusty bolts to soak in penetrating oil for a brief period. For optimal results, liberally repeat these soaking sessions using a high-quality penetrating oil. In instances of exceptional stubbornness, contemplating an overnight soak might be a worthwhile option before exploring more drastic measures.

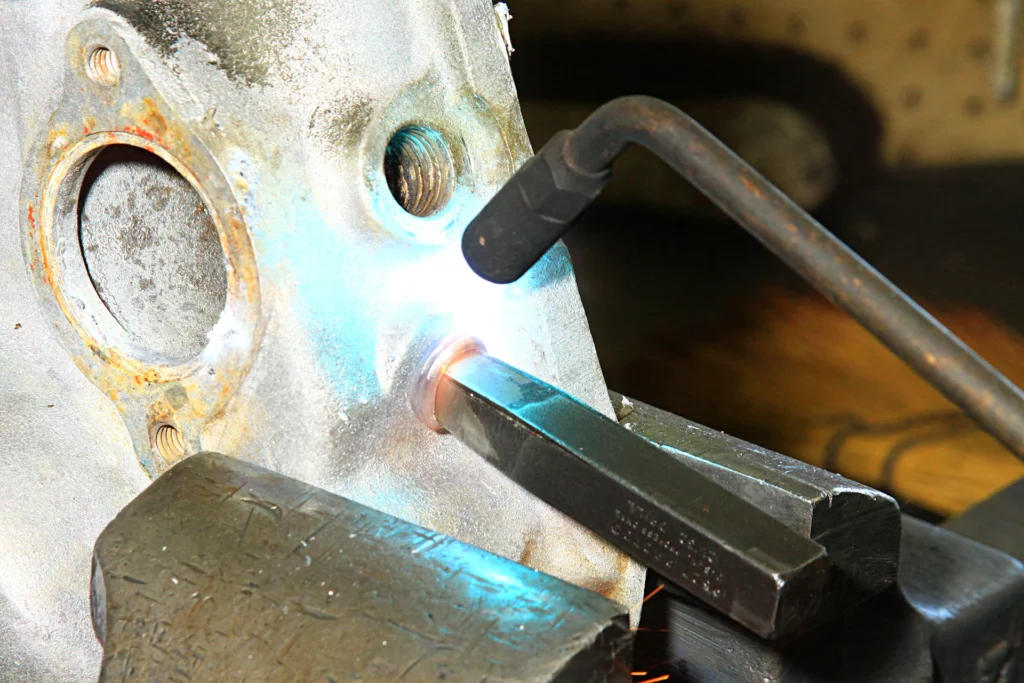

Step 7: Employ Heat

Leverage the effectiveness of heat in breaking the bond between threads and bolts. Safely utilize either a propane torch or a heat gun to carefully heat the area surrounding the seized bolt. Once the area has reached an appropriate temperature, cautiously attempt to turn the bolt using a wrench or pliers.

Step 8: Harness Impact and Vibrational Forces

Unlock the potential of impact and vibrational forces to successfully free seized bolts:

- Position a chisel against the bolt’s edge and gently tap it with a hammer to disrupt the bond.

- Alternatively, apply rotational pressure with a wrench while concurrently tapping the bolt with a hammer. This combination of forces can often triumph over the resistance encountered.

Exploring Alternatives

Should the previously mentioned methods prove ineffective, there exist alternative techniques for dealing with seized bolts.

Gaining Optimal Leverage

For tackling a stubborn bolt, utilizing a breaker bar is optimal. The key lies in employing finesse and distributing pressure uniformly. It’s crucial to avoid excessive force to prevent thread stripping; commence with gentle pressure and escalate as necessary.

In cases of reduced resistance, either thread stripping or bolt damage might be occurring, underscoring the importance of wearing protective gloves.

Paraffin for Lubrication

Professionals adeptly manage rusted pipe plug removal from cast iron utilizing the following steps:

- Heat the iron to melt a candle over the threads.

- The melted paraffin forms a lubricating layer on the threads.

- Employ a well-fitting, appropriately sized socket.

Last Resort Measures

Further, In confined spaces where an overtightened nut is ensnared, employing a pneumatic or electric impact gun becomes necessary for liberation. For optimal safety, don protective gloves and eyewear when utilizing this high-powered tool, especially with larger nuts. If feasible, use the gun to dislodge the entrenched nut while grasping the bolts with a wrench.

Considering Professional Assistance

In instances where the removal of a bolt lacking a head becomes excessively intricate or hazardous despite earnest efforts, enlisting professional aid is prudent.

At last, a skilled mechanic or technician possesses both the know-how and specialized tools to address even the most stubborn bolts. This avenue saves time, averts further harm, and ensures a secure and efficient resolution.

Top 5 best strategies for removing a seized bolt without a head

Strategies for Removing a Seized Bolt Without a Head

To address the challenge of removing a bolt without a head, consider these steps:

- Apply Penetrating Oil: Begin by applying penetrating oil to the bolt, allowing it a few minutes to combat rust or corrosion. This prepares the bolt for removal by loosening its grip.

- Use Pliers or Wrench: Employ pliers or a wrench to grasp the edges of the bolt and turn it counterclockwise. This method often works to release the bolt from its seized state.

- Drill and Tap: If conventional methods fail, contemplate using a drill to create new threads on the bolt. Drill a hole in the bolt’s center and utilize a tap-and-die set to establish fresh threads.

- Left-Handed Drill Bit: Should the bolt remain stubborn, employing a left-handed drill bit can be effective. These bits rotate counterclockwise, assisting in bolt removal.

- Cutting Wheel or Hacksaw: As a last resort, employ a cutting wheel or hacksaw to cut the bolt and subsequently remove it.

It’s imperative to note that employing heat to loosen the bolt is discouraged, as it might harm the surrounding area and weaken the bolt.

Maintenance Recommendations

To ensure the longevity of bolts and facilitate future removal, consider these maintenance ideas:

- Lubrication: Regularly apply lubricants like oil or grease to bolt threads, which prevents the growth of rust and corrosion. This step significantly eases bolt removal later on.

- Anti-Seize Compound: Applying an anti-seize compound to bolt threads serves a dual purpose: preventing rust and corrosion while also simplifying future removal efforts.

- Proper Tightening: To prevent bolts from seizing, always use the appropriate torque when tightening them. Overtightening can lead to challenges during removal.

- Environmental Protection: Shield bolts exposed to the elements by applying a rust inhibitor or utilizing protective paint to prevent rust and corrosion.

- Regular Inspection: Routinely inspect bolts and fasteners to identify issues like rust and corrosion before they escalate into seizing problems.

- Maintenance Cycle: For long-term usage, periodically remove, clean, and reapply lubrication and anti-seize compounds to ensure continued ease of removal.

FAQ

What is a bolt with no head?

a bolt with no head is commonly referred to as a “stud” or a “stud bolt”. On the other hand, if the bolt possesses a head but lacks a slot, socket, or gripping mechanism, it is known as a “carriage bolt.

How can you force a bolt out?

you can employ a method to force a bolt out using a Bolt Extractor Set:

- Place a socket over the bolt head.

- Gently tap the socket with a hammer to ensure a snug fit.

- Attach the socket wrench handle to the extractor socket.

- Turn the wrench counter-clockwise to let the extractor socket grip into the metal, causing the bolt to turn out.

Is a headless bolt called a stud?

Yes, a headless bolt is indeed called a “stud bolt.” These fully threaded bolts lack a head and are commonly used to join pipeline flanges. Their advantage lies in the ability to be tightened from both ends by using nuts.

Can oil loosen bolts?

Yes, penetrating oil can be used to effectively loosen bolts and screws that have become stuck or corroded over time. The low viscosity of the oil allows it to quickly penetrate into crevices, grooves, and pores, making it useful for items with moving parts, such as cars or bicycles.

Conclusion

To wrap up, It can be a challenging task to remove a seized bolt that has no head in the world of do-it-yourself tasks. However, this ostensibly difficult task may be successfully completed if you are equipped with the appropriate tools, tactics, and a patient mentality. You can maneuver through the complexities of rust, resistance, and stubbornness by carefully following the instructions provided in this guide.

Furthermore, Remember that while every circumstance may call for a somewhat different strategy, the fundamental values of planning ahead, showing patience, and endurance never change. The joy of solving this mechanical problem and regaining control over the circumstance can be extremely satisfying with the right precautions and a deliberate approach. Therefore, learning the technique for releasing a seized bearing can help you no matter if you’re working on a project at home or fixing an automobile.